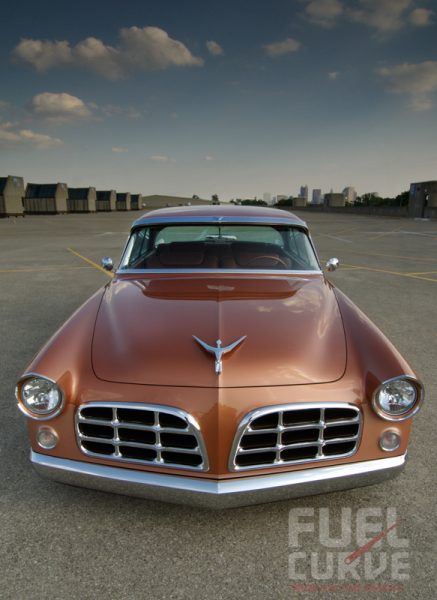

1956 Chrysler 300B – Rolling Perfection

Story and Photos by David Fetherston

When Roger Ritzow decided on having the ultimate Chrysler 300 built for his wife Nancy a few years back, he chose friend and supreme craftsman Troy Trepanier of Rad Rides by Troy. Roger had already read the glove box handbook that came with every 300. It said: You have just purchased the most powerful production car in America. Those are fighting words, alright, wrapped up with a closing statement that: Your 300B stands apart from its highway brothers in three significant ways … performance, ride and beauty. . .” That was enough for Roger!

Roger and Troy got talking at a show one afternoon about building car for Nancy. They were wandering around cool fifties cars when the 300 came into the conversation. Roger knew that the 300 was without doubt a car worthy of Troy’s touch, and Nancy loved the styling. Let’s do it! was Nancy’s and Roger’s challenge. It took a while, but Troy sourced a clean 1956 Chrysler 300B Newport in Arizona for just a tad over $10,000.

Within a month under Troy’s supervision, it was discovered to be rust free and cherry. The car had never been crashed and the rest of the sheet metal looked pristine when it was all stripped.

One target was to make the car look as factory perfect as possible. The nose was welded into one piece, while the headlights were frenched with new custom made inserts. Some of the trim was shaved off and new lower side trim was created. The major body objective was to have slick smooth sheet metal, perfect doors, hood, and trunk gaps. After solid six months of body work, the paint and interior colors were selected by Nancy. Charlie Hutton shot on the three-tone mix of color in BASF Glasurit colors named Nancy Rose and Charley Brown.

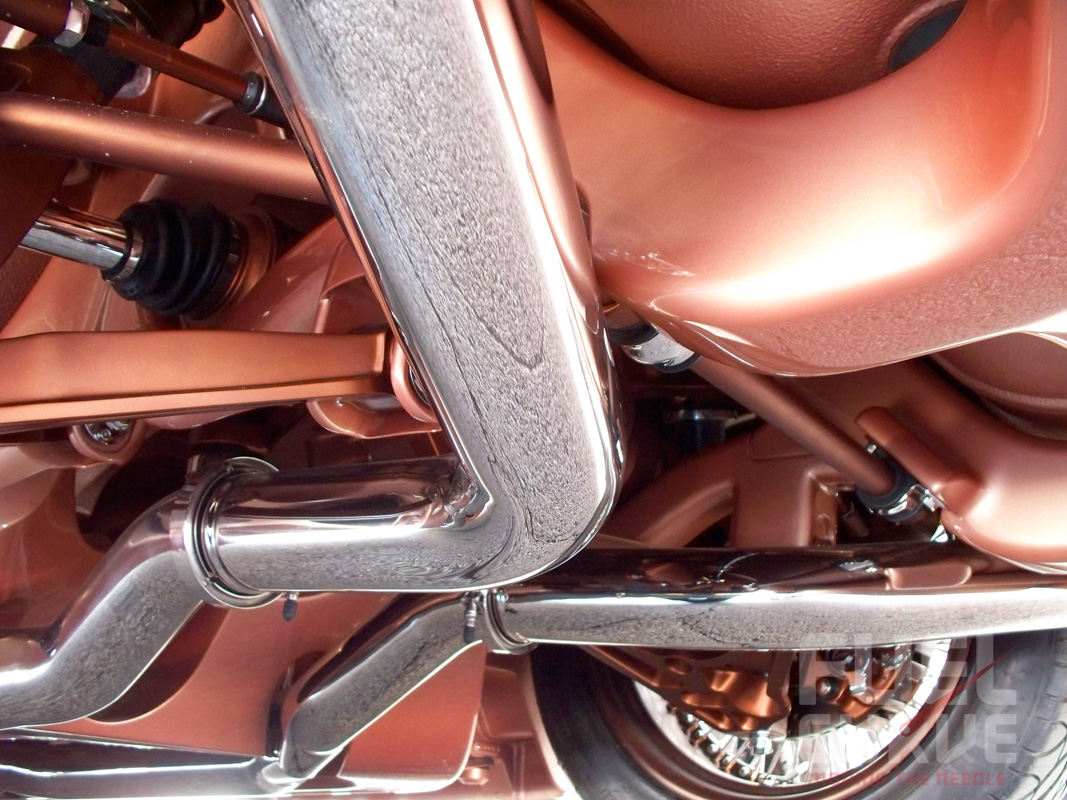

Troy designed a fresh new chassis underneath using ’07 Viper front and rear suspension. Two main rails were formed with the single transmission cross-member set across the frame featuring an oval pass-through orifice. The rear cross-member supports both the suspension and body mount. The Viper rear was narrowed four-inches, which meant the addition of new Moser 36-spline axles and new 1,000 lbs Hypercool springs in the coil-over packs.

The wheel department saw a set of Dayton Wire Wheels with true knock-offs, using three-piece alloy rims, brushed triple stainless spokes, painted alloy hubs and copper plated nipples. The front rims are 19 X 8s, while the rears stand at 20 X 10s. They emulate the chrome-look Kelsey-Hayes wires that could have been factory for the coupe. The rotors are cross-drilled 13-inch Baer units clamped with Viper four-piston calipers to help slow the 300, which has a standing road weight of 4,235 pounds.

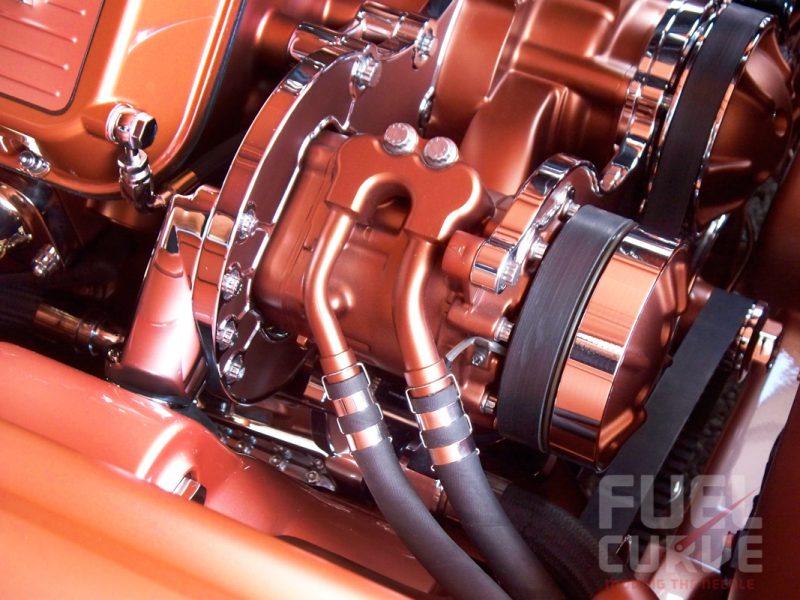

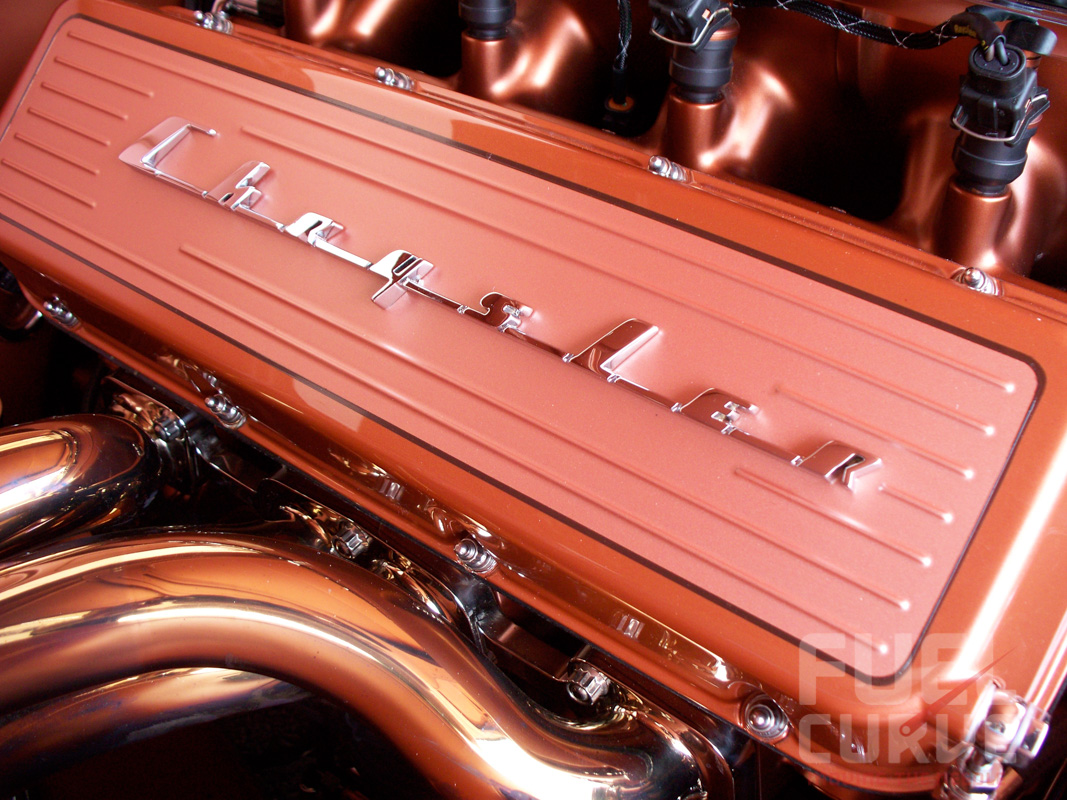

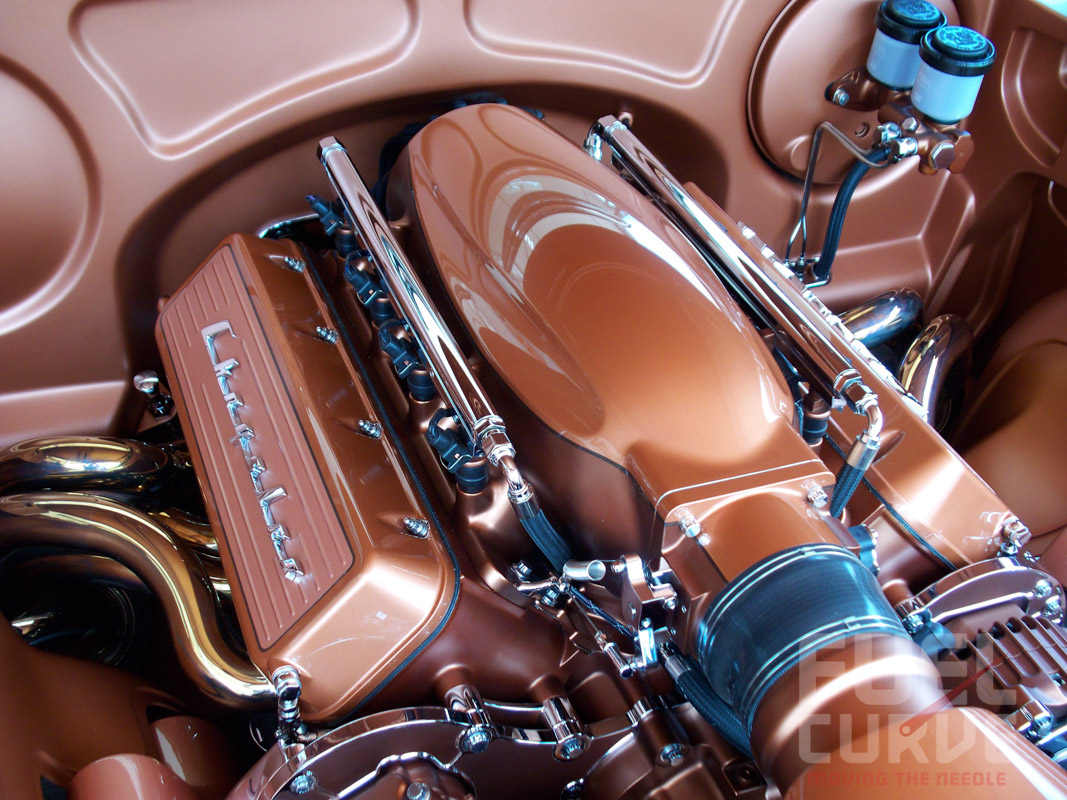

All along, the project was going to be Mopar-powered, but not the OEM Hemi package. Some digging about produced a 358 cubic-inch Dodge Nextel Cup R5 racing engine with a 4.180 bore on a 3.26-inch stroke. Troy had Bob Care at Jesel Racing build the engine after they had prepped and painted the block and heads externally. Nothing internally is stock, as you might imagine, including the oiling system which runs a 12-quart dry sump tank and a Daily six-stage dry sump pump.

The induction is way more complex with its Griffin Radiators intercooled, twin turbo setup. Troy engineered the induction to mostly hide within the bodywork by mounting a pair of 70mm Precision turbos behind the inner fender wells, along with their matching waste gates and ducting. The guts of the induction are an extensively reworked Wilson manifold running a 105mm Wilson throttle body, and a GM three-bar MAP sensor that is capped with new air delivery plumbing.

The turbo is driven off a pair custom-made Rad Rides Turbo Headers made of 1-7/8-inch stainless/titanium. The exhaust is eventually hushed via 3.5-inch Flowmaster hardware.

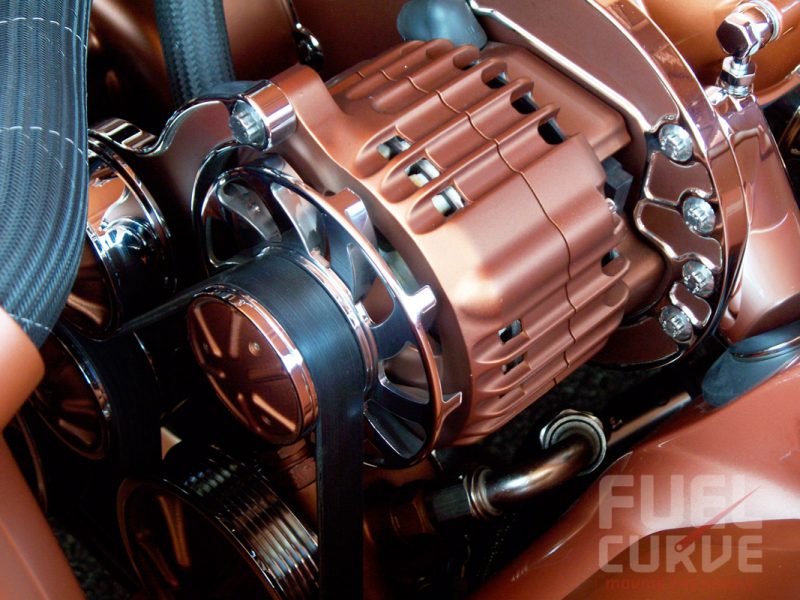

The engine is fully finished-out, as one would expect of Rad Rides, with paint, powder coating, and chrome. One of the new Rad Rides Accessory Drive set ups runs the Viper water pump, Powermaster alternator, A/C, and power steering pump.

A John Meaney-built, Big Stuff-III EFI controller keeps it all in check. John is the king of programming wild engine setups and his controller gives the 300 a meek and mild drive-about-town feel. But just stamp the throttle and feel you ears press back from the brutal power delivery. Then just drive it like you’re cruising again; it’s seamless between the two power options. It makes an estimated 850hp.

According to Troy: 850hp is is in the ballpark. Putting power out the rear wheels meant making sure the slush box had enough slush. Troy took a GM 4L80E four-speed automatic and built a custom transmission adaptor before delivering it to Bowler Transmissions for a heavy duty build. But what is really trick about the transmission is how Troy set Jared Zimmerman to work on the dashboard electronics. First was the pushbutton, dash-mounted shifter module.

Jared dumped all of the factory hardware, bar the actual button selection unit, and created a complete new electronic servo-activated gear selection that works flawlessly. Jared also reconfigured of all the dash controls, including the A/C controls to operate the new Vintage Air air-conditioning installation. In fact, all the original switching operates new systems using a multi-plex wiring harness; even the radio is reconfigured. All mighty cool trick stuff!

The steering wheel was made of a single 150 pounds chunk of aluminum. Troy’s top-notch machinist Lawrence Laughlin created it right in the shop, and with the help of Jared, added paddle shifter buttons on the back of the spokes 180 degrees apart.

The Ritzows wanted to stay OEM-looking with the interior on their 1956 Chrysler 300B which had a bird-patterned fabric that they loved. Unfortunately, it was no longer available in the color they wanted.

Troy tracked down a mill in Pennsylvania who made the cloth and soon enough he had 40 yards of Rose Birdcloth custom milled to create for the interior soft facings. Troy is really particular about his interior work and had Jim Griffin from Bend, Oregon come to his shop in Manteno, Illinois to do stitching in-house.

In the years since its debut, it has won awards in Detroit to Arizona and has been driven on the Goodguys Hall of Fame Road Tour.

In someways, there is more than enough of everything about the Ritzow’s 300. Street machines aren’t necessarily getting wilder, they’re getting way more sophisticated and drivable. Once again, Trepanier and his team lead the way . . .