Darkhorse Double Down – John Wityak’s 1965 Mustang

The Evolution and Eventual Rebirth of An AutoCross 1965 Mustang

Words & Photos by John Wityak

I’ve always been a gearhead. Growing up in Connecticut in the 1960s, my dad and I regularly attended races at Connecticut Dragway, Stafford Springs Speedway, and an annual pilgrimage to Lime Rock for the Trans-Am date. I modified my matchbox cars in the days before Hot Wheels and was always taking things apart to see how they worked. When I built model cars, I never built the stock version.

My first car was a 1970 Mach 1 that I owned fresh out of high school in 1976. I rebuilt the 351 Cleveland with a lumpy cam and installed a top-loader four-speed. I loved that car but couldn’t afford to put gas in it during the second oil crisis of 1979 and had to sell.

Fast-forward to 1988, now married and a chemistry post-doctoral research associate at Stanford University, I bought a black plate A-code 1965 Mustang that was in solid but sad shape with a partially installed 302c.i. V8. I swapped in a 289/three-speed manual and, working in our apartment carport, went through the mechanicals and eventually had her painted Rangoon Red by a small restoration shop.

Round One. The blurry photo of the blue convertible is where the project started in 1988, and much of the first rebuild happened right there in the carport of our apartment complex. After being painted by a local resto shop, the Rangoon Red beauty was ready for the road again in an essentially stock configuration with a 289c.i. V8 and three-speed manual transmission.

Restomod Refinements

I continued refining the 1965 Mustang while driving her daily. She moved with us to the East Coast in 1989 and back again in 2003 as our family grew; she would move with us a total of six times. After moving to San Diego, I installed disc brakes, a Tremec T5, and a traction-loc differential – transformational changes that made her a truly enjoyable restomod driver.

In true gearhead fashion, I made more upgrades through the years, installing a 347c.i. Windsor small block, Global West subframe connectors, TCP manual rack-and-pinion steering, and a Flaming River column. I had a shop install a canted four-bar coil-over rear suspension, added Chrysler Sebring convertible seats with integral shoulder belts, and added fuel injection using a 1990 Mustang wiring harness and computer.

AutoCross Addiction

In 2006, I attended my first Goodguys event in Del Mar and got hooked on these happenings. When Goodguys began holding AutoCross at Del Mar in 2010, I was in. I wasn’t fast, but it was such an adrenaline rush that I knew I’d found a new passion.

– I became seriously addicted to AutoCross after Goodguys began having competitions in Del Mar in 2010. The Mustang evolved again, with a variety of front suspension modifications, wide wheels and tires, Corbeau bucket seats, four-point harnesses, and an 8-point roll bar.

Goodguys CPP AutoCross motivated me to update the front suspension using home-brewed modifications to improve geometry. I also installed Maier Racing fiberglass flared fenders, allowing for 285mm rubber. The four-bar rear suspension didn’t hold up to the increasing abuse, so I reinstalled the leaf springs. I had Outlaw Motorsports install an 8-point roll bar to further stiffen the chassis and added Corbeau CR1 buckets with four-point harnesses.

In August 2015, my friend and fellow AutoCrosser Richard Trujillo invited me to a Race Legal event – a 1/8-mile drag race held at Qualcomm Stadium near San Diego. We enjoyed making runs through the day and, with nightfall approaching, we lined up against each other for one last race. I’m sure I left on him, but it wasn’t long before he drove around me as I struggled for first-gear traction. In third gear and through the traps at 80mph, I hit the brakes and the pedal went straight to the floor.

With the end of the track approaching rapidly, and in a panic, I drove around what I learned later was a water barrier. I didn’t think to downshift. Additionally, I knew my parking brake was non-functional; the cables for the floor-mounted hand brake had rubbed the driveshaft so I had removed them, intending to someday reposition them.

The track was perpendicular to a busy four-lane highway protected only by some curbing and a wooden barrier. Not wanting to make a bad situation worse, I attempted to spin the car, instead crashing over a curb and destroying the front wheels. Now on the grass, I was just along for the ride. I hit a steel pole on a large concrete mount at probably 50mph. I clearly remember my head snapping forward and the car flying up the pole.

Ouch! That hurt. While competing at a street-legal 1/8-mile drag race event in 2015, I lost the brakes and hit this steel pole, wiping out the front end of the Mustang and shoving the engine back into the firewall. Amazingly, the windshield was not broken.

Once I landed, I unbuckled, got out, and surveyed the damage, which was extensive. My neck hurt and would be sore for months. Despite my full-face helmet, I had a black eye and my ribs were bruised. There was a witness mark around 10 feet up that pole. I had the Mustang towed to my friend George Reiss’ shop, Reiss Racing and Restoration, and went home for the night.

Bigger, Faster, Stronger

Inspection the next morning revealed that the engine had been pushed up and back. The firewall, floor, cowl, dashboard, driveshaft, and headers were bent. The hood and front apron were obliterated. Incredibly, the windshield was intact and the roll bar appeared undamaged. I found a small hairpin cotter pin on the floor – its job to keep the brake pedal connected to the master cylinder push rod. It must have vibrated loose.

I should have ensured that I had a working parking brake – that was a serious mistake and a lesson learned the hard way. Having owned this 1965 Mustang for nearly 30 years, there was never any doubt that I would rebuild, and I wanted her to be better than ever – safer, faster, lighter, stronger, and prettier.

Before the accident I’d become obsessed with suspension design as a mostly theoretical exercise. Now I had a clean-sheet opportunity to apply what I’d learned. With the help of friends, I was all in.

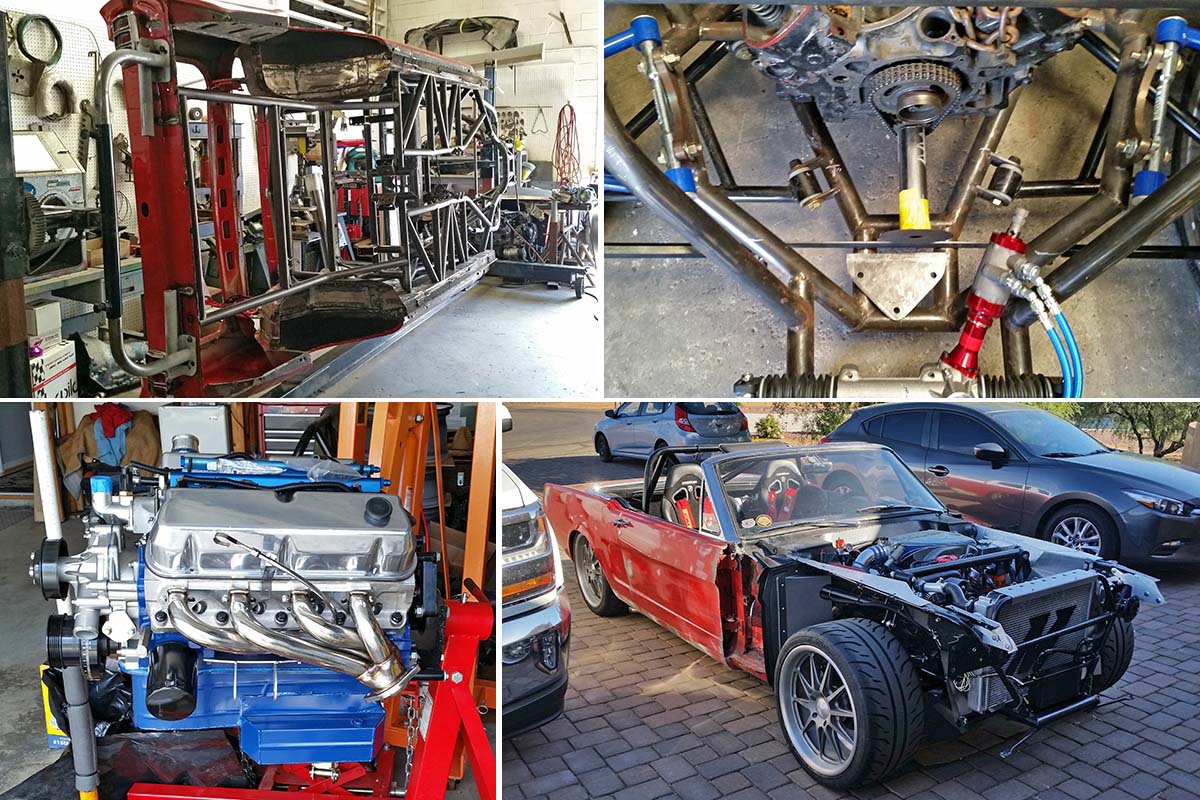

Bigger, faster, stronger. I went all-in on the final rebuild, having Reiss Racing and Restoration build a custom chrome moly frame that would accept front and rear suspensions that I designed. I rebuilt the 347c.i. stroker small block and we set the engine further back in the car for better weight distribution and handling.

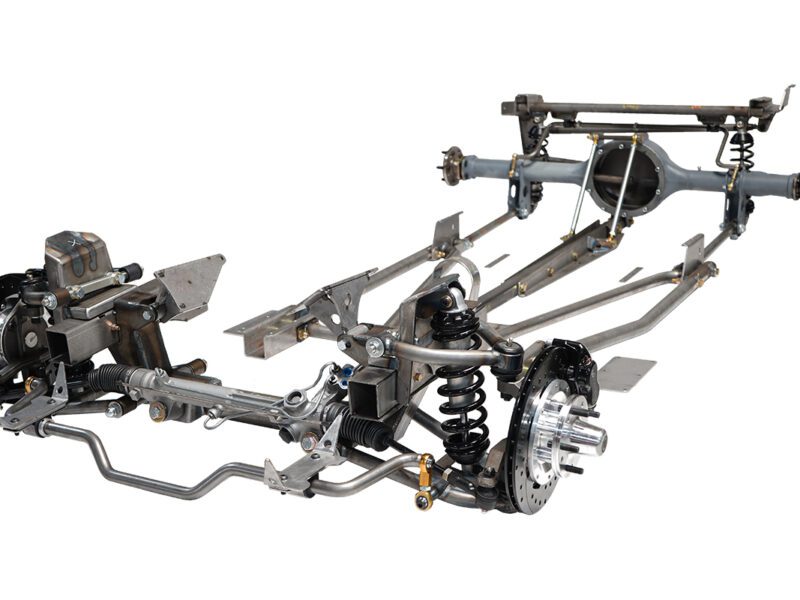

The front and rear suspensions were designed around 305mm tires, a specific ride height, and adjustability for instant center length, roll steer, anti-squat, and anti-dive. Mike Maier had told me about a Satchell link, which is a four-link rear suspension with converging lower links and parallel uppers first designed by Terry Satchell. If carefully engineered, it does not bind, can have favorable SVSA length, excellent anti-squat, passive roll understeer, and decent roll center height.

I designed a double A-arm front suspension inspired by a second-gen Camaro using Howe Racing upper and lower control arms. Other chassis hard parts included Speedway forged 2-inch drop spindles, a Woodward Steering power rack and pinion, and significant engine setback to help lower the polar moment of inertia and achieve 50/50 weight distribution.

The coil-overs would be mounted as close to the wheels and as upright as possible to maximize spring motion ratio. The wheels would include 305mm rubber on 11×19-inch rims in a squared setup so the wheels could be rotated to even out wear. When you’re on a budget and paying for your own rubber you need to make it last!

Additionally, the hairpin cotter that failed would be replaced by a locking variety and the parking brake would be made functional and mounted C4 Corvette style, to the left of the seat to avoid the driveshaft.

Following a move to Arizona, I finally got the car running again in late 2019 and was able to compete in a couple AutoCross events with the car looking a little like Frankenstein’s monster. Here it is at the 22nd Speedway Motors Southwest Nationals in Scottsdale in November 2019. (Terry Lysak photo)

George, his fabricator Jacob Tilis, and Richard helped dismantle the car and we ultimately cut out the floors, trunk, front subframe, firewall, and cowl. The body shell was squared and braced and George built the frame from 1¾-inch chrome moly tubing with my input regarding suspension pickup points. George and Jacob also mini-tubbed the rear wheel wells and handled the sheet metal work on the firewall, floors, and trunk. While this was happening, I had the engine at my house, replacing damaged parts and having it machined so I could rebuild it.

I took a TIG welding class at the local community college, which gave me enough confidence to weld tabs on the chassis to mount brake lines, fenders, inner fenders, and various tanks and coolers. I shaved the rear bumper and fitted the ends. I wired the car using a Painless Performance panel and bought an industrial sewing machine that I used to trim the interior.

Final Stretch

More life changes happened around this time, including a career change and a move to Tucson, Arizona in 2018. The desert is beautiful and the winters are mild, but the summers are long and HOT! Thank goodness for air conditioning. We even air conditioned our garage, which was money well spent!

At the time of the move, the Mustang could steer and brake but was not running. I finished building the front splitter and rear spoiler and working on the front apron and fenders. A foam mold for a Trans-Am-inspired air extractor was sculpted, fiberglassed over, and the piece ’glassed in place on the right fender. I enlisted a talented local welder, Dylon Vaugh, to re-weld some chassis brackets that needed to be moved for clearance. Alex Arvizu helped me modify the angled upper and lower control arms for clearance with the high-backspace wheels. He had a tube bender capable of making tightly radiused S-bends and was an artist with a TIG torch.

With the fabrication completed, I could fully focus on getting her running again. After chasing down some ignition issues, I had her running well again in late 2019 and with some trepidation (and AAA on speed dial), I took the first shakedown drives. Success! I worked out some bugs and was able to participate in an SCCA autocross that October and the Goodguys Southwest Nationals in November, with my car looking like a science experiment!

During the build I made countless renderings to visualize how the car would be finished. I settled on a ’68 Mustang-inspired C-stripe scallop and another stripe to accentuate the hood. In December 2019, I dropped her off at Wild West Rods & Custom in Tucson for paint and bodywork. Shop owners Randy and Billie Green allowed me to participate and help with disassembly, sanding, and reassembly. The Mustang was finished using PPG materials in glossy WRX Blue Mica, with matte finish BMW Sterling Grey and Chrysler Viper Silver graphics. Joe Gaskell applied the paint and did the final buff.

In 2020, the Mustang was treated to new bodywork and paint by Wild West Rods & Custom in Tucson, using PPG materials in glossy WRX Blue Mica color with matte finish BMW Sterling Grey and Chrysler Viper Silver accents. After 30-plus years, the Mustang is still evolving and growing with me, and I can’t wait to see how the latest incarnation performs on the AutoCross track.

In a lengthy and complicated build, I knew that it would be essential to maintain momentum. At times it would ebb or build due to job loss, a move, waiting on parts, scheduling, and a worldwide pandemic, but it was never completely lost. I couldn’t have done it without the support of my wife Ellen, a car lover and our family banker, plus the help of so many others I’ve tried to mention in this story.

The end of the build was a long time coming. It was an amazing journey and extremely gratifying as tasks were ticked off and plans came together. My spreadsheet for the build had close to 500 line items and an estimated 3,000 hours of my own time. I enjoyed almost every minute, learned a lot along the way, and loved the problem-solving aspects of the build.