Forgeline Wheels – Two Decades of Track Tested Technology

Forgeline Wheels is the original American made one-off racing wheel manufacturer. With over twenty years of applied experience supporting enthusiasts and factory race teams from the drag strip to road racing, their technology has trickled down to the world’s most incredible street cars. Forgeline wheels regularly appear on America’s most heralded street machines and AutoCross cars and it’s no wonder. They’re strong, stylish and built to perform.

Their wheels are used on the unreal Glickenhaus SCG 003 endurance race machine and the Forgeline GS1R is the factory-homologated race wheel for the GT4 class Chevy Camaro and Ford Mustang. Forgeline is the only US-made wheel company in the GTS field and yet anyone can custom-order a set for their own car.

All of their forged wheels are manufactured under one roof right here in Dayton, Ohio using all-American engineering, hardware, and craftsmen. Don’t expect to find any shop or store to have Forgeline wheels in stock, because every set is custom ordered and built to spec.

So what is it that makes Forgeline deserving of your hard-earned cash when choosing wheels for your racecar or next-level street build? To really get an understanding of what separates Forgeline from the rest we stopped by their manufacturing facility in Dayton to take a closer look at every step of the process and dive into the Forgeline history books.

Before heading onto the factory floor we took a walk around the office to learn how Forgeline got its start back in 1994. In reality, Dave and Steve Schardt, the twins behind Forgeline, got their start with wheels years before the 1990s came around. Their father purchased then-failing Dayton Wire Wheel company and turned it into the successful and well-respected manufacturer it is today.

Working summers and nights in the wheel factory from a young age, the Schardt brothers had wheels in their blood growing up. Dave started a wheel distribution company which he eventually abandoned ship for in favor of Steve’s custom racing wheels workshop.

Of course, that workshop was Forgeline and the Schardt’s are exactly the type of people you’d trust to make a product they truly stand behind. In Dave’s office you’ll find prototype wheels, awards and plaques dedicated to racing successes, and scale models of racing legends over the years.

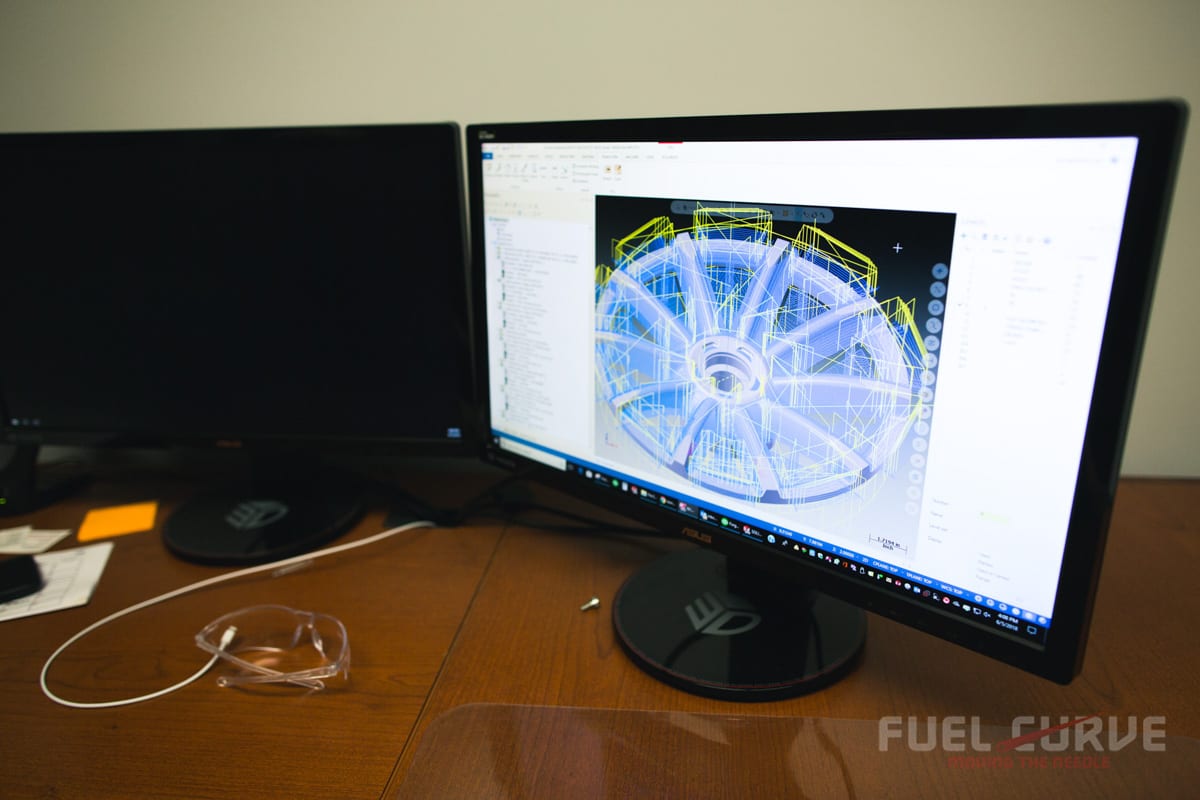

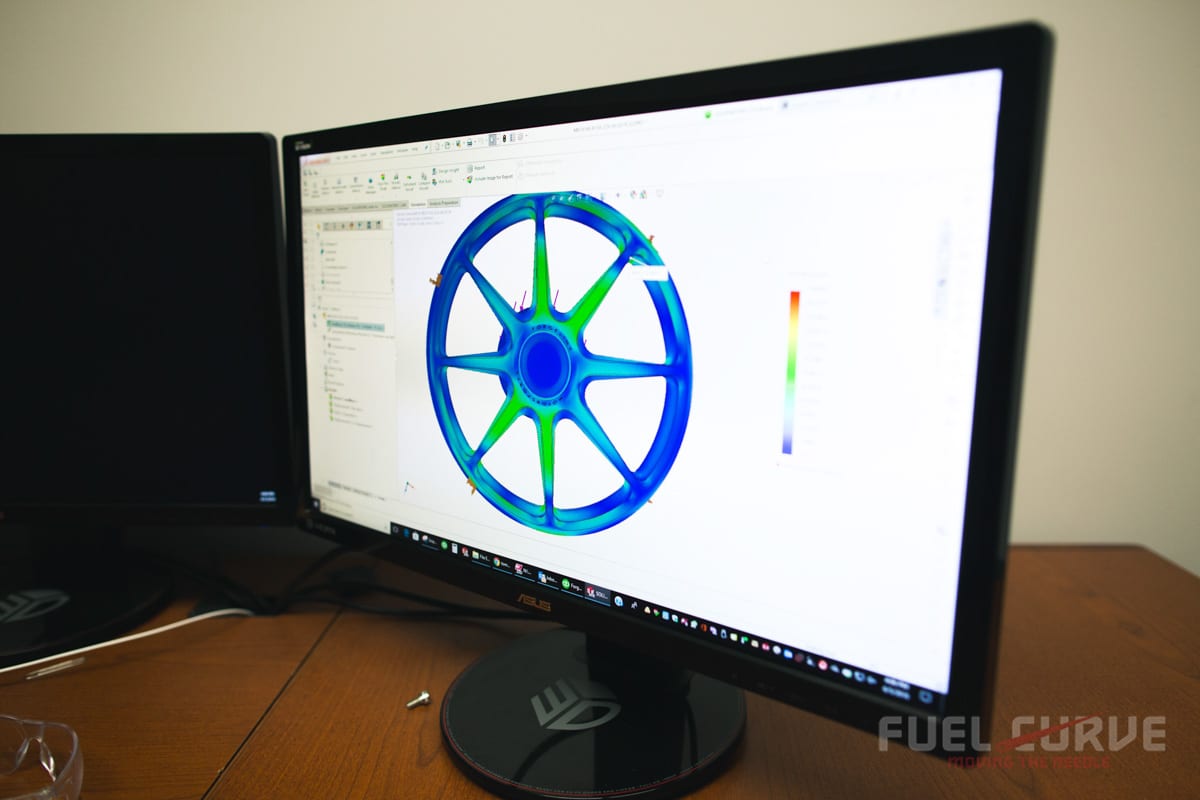

Moving on to Todd Larue’s engineering office we took a look at how every individual wheel actually gets its start. From rough sketches to perfect 3D models, the wheels are then tested through a variety of finite element analysis (FEA) simulations which show how the wheel stands up to a variety of external forces and torque loads.

Before these designs come into play on the manufacturing side of things, each wheel starts as a forging from Forgeline’s partners in California – Aluminum Precision Press. While they don’t look like much at this point, these high-strength parts are the base of everything Forgeline does. More recently in addition to their aluminum barrels, Forgeline has added a carbon fiber option to their lineup.

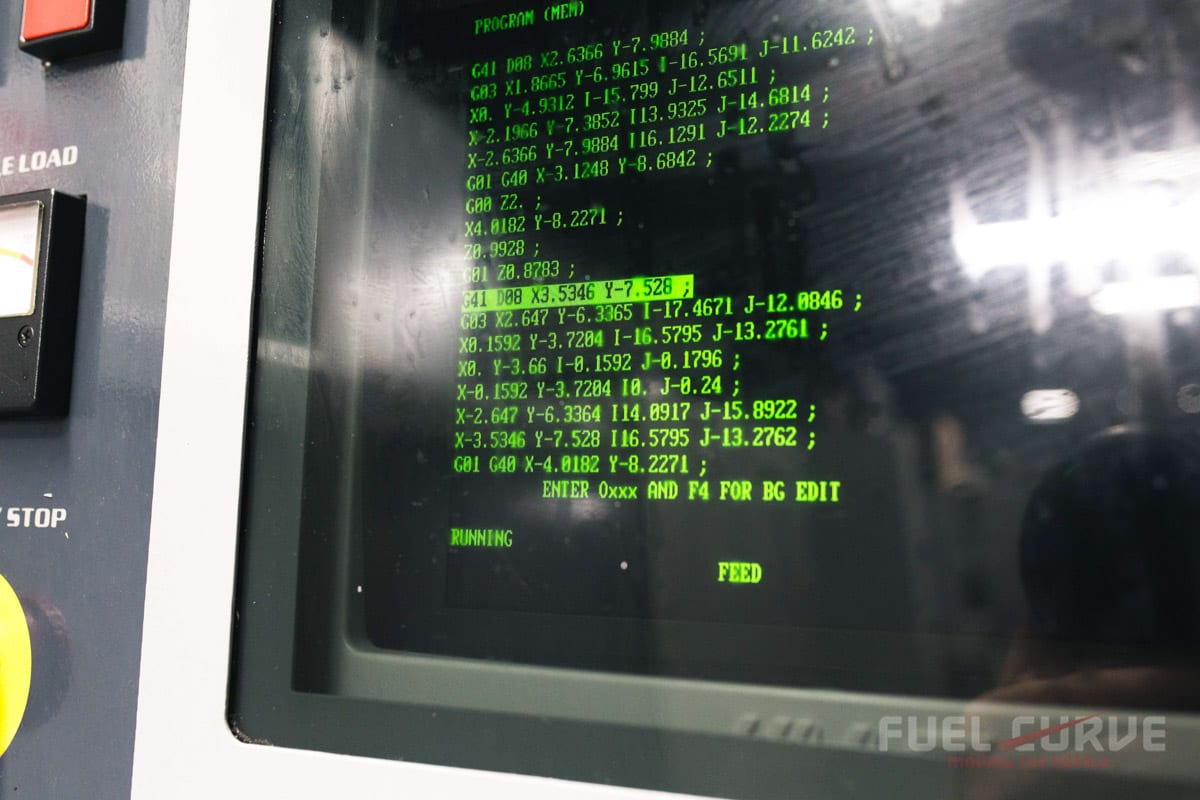

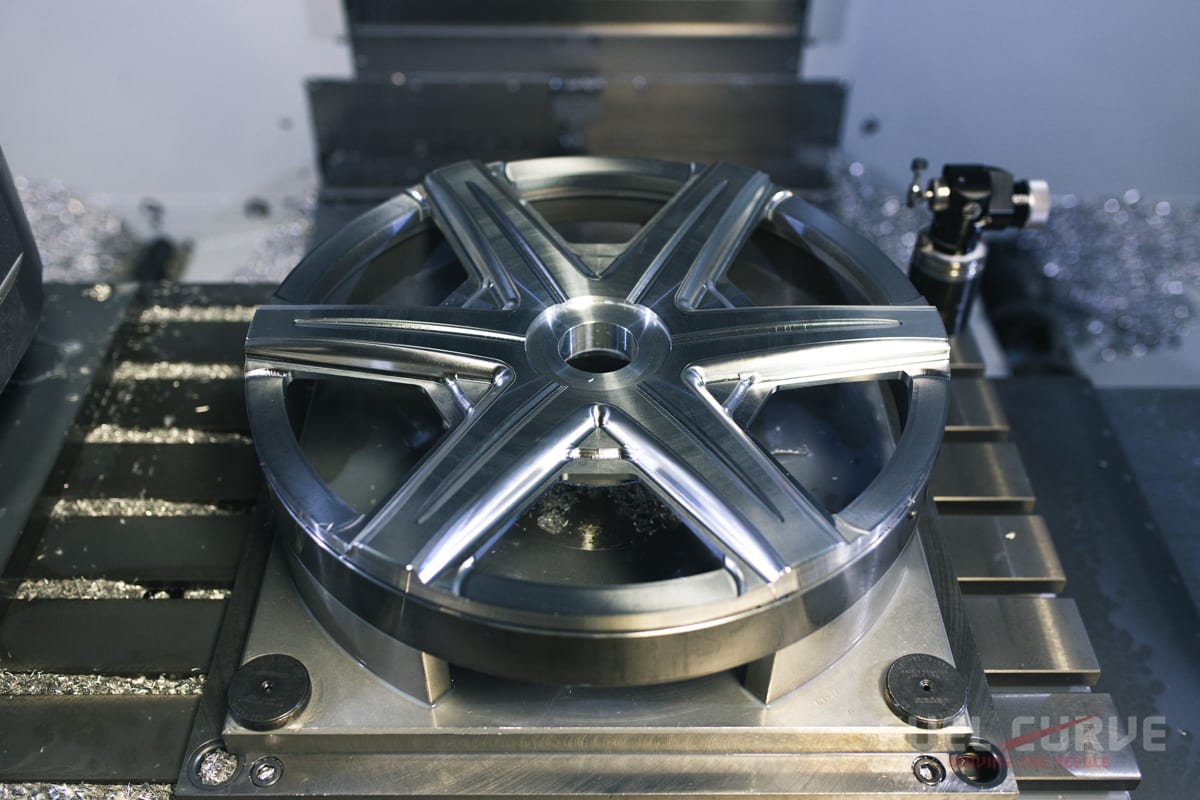

Three-piece, carbon barrel, or one-piece forged wheels alike, everything goes through multiple, complex machining stages in CNC mills and lathes in a humidity and temperature-controlled work station. After loads of engineering trickery, the semi-automated portion of the process is complete. Lets just say this is a factory that makes lots and lots of recyclable chips and shavings.

After the wheel centers are out of the CNC machines they’re fitted with Heli-Coils (so that the wheels can be reliably re-assembled or serviced later on) and they’re ready for the next step. Anyone with machining experience knows that no matter how precise your process you’ll end up with small burrs and imperfections that wouldn’t be acceptable in a finished product.

This is where manpower comes in with wheels stocked up for highly skilled craftsmen to put their magic touch on the machined parts. With Forgeline’s exceedingly high standards and each wheel requiring a specific finish, the guys in this room are an essential part of the equation.

From here the wheels are ready for Forgeline’s in-house powder coating process. Again, skilled American hands are used to clean, prep, spray and bake the wheels. There’s a specific, delicate and engineer-approved recipe Forgeline uses to ensure that the forged wheels aren’t annealed (softened) in the process.

Thanks again to John Comeskey for showing us around the Forgeline Wheels factory during production, and the entire team for continuing to build wheels without compromise. We’ll see you on the track!