Get Ready, Get Set! The Basics of Preparing for EFI

So, you’re finally getting ready to treat yourself and your hot rod to the benefits of an electronic fuel injection system! In this day and age of advanced technology combined with lousy blends of fuel that easily corrode and wreak havoc on older fuel systems, stepping up to EFI is a solid upgrade.

There are plenty of inventive fuel injection companies that offer self-learning EFI systems to bolt in place of a carburetor these days. Better yet, you don’t need to rent dyno time or have a computer engineering degree to set up or tune-in your new system, as most throttle body EFI systems can be tuned from a hand-held monitor. If you can share a contact from your phone, you should be able to set up your new EFI system. (If not, get a hold of your 12-year-old nephew to help.)

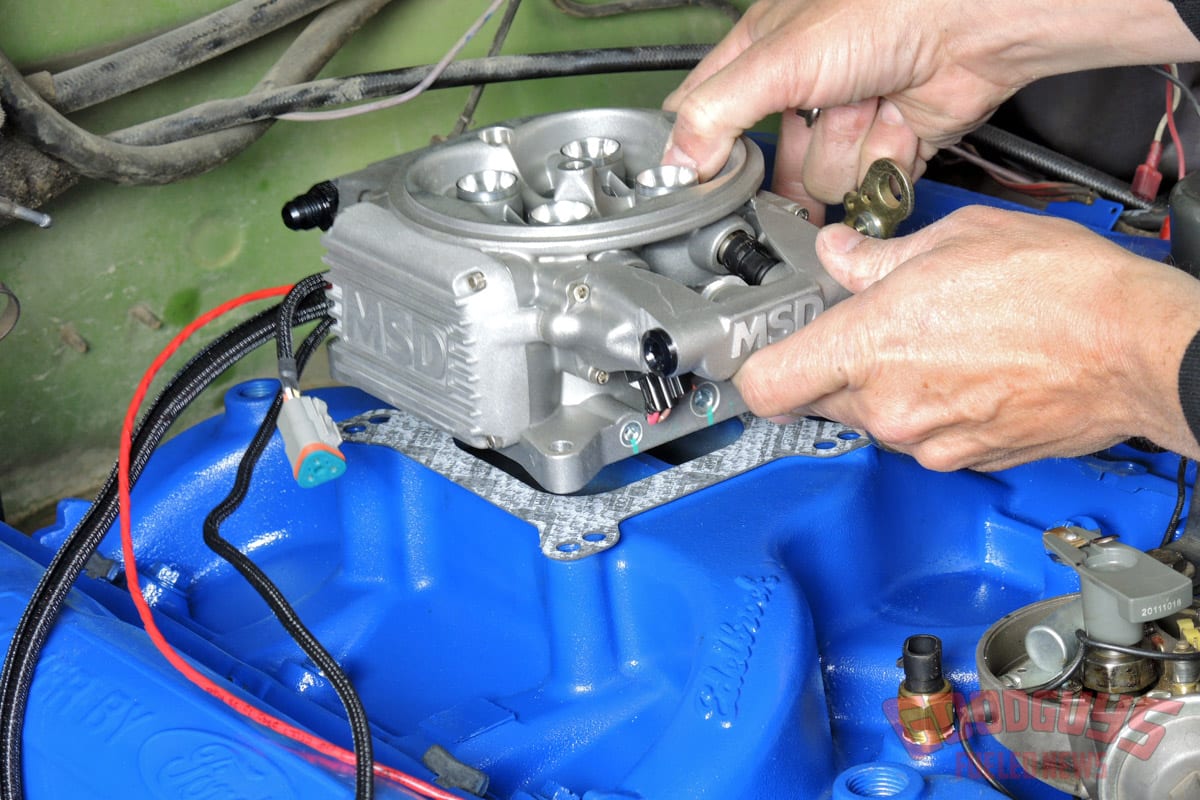

This new Sniper EFI 2GC system is supplied with a complete wiring harness, handheld tuner, oxygen sensor and more, but you still need to plan out your fuel system, wire routing and other details.

As much as EFI manufacturers provide in their kits, and no matter how easy they make their throttle body or intake to bolt in place, there will be always be some extra work involved in completing the swap. A good installation and optimum performance will also depend on how detail oriented you are with the wiring, fuel lines, and accessory component mounting and placement.

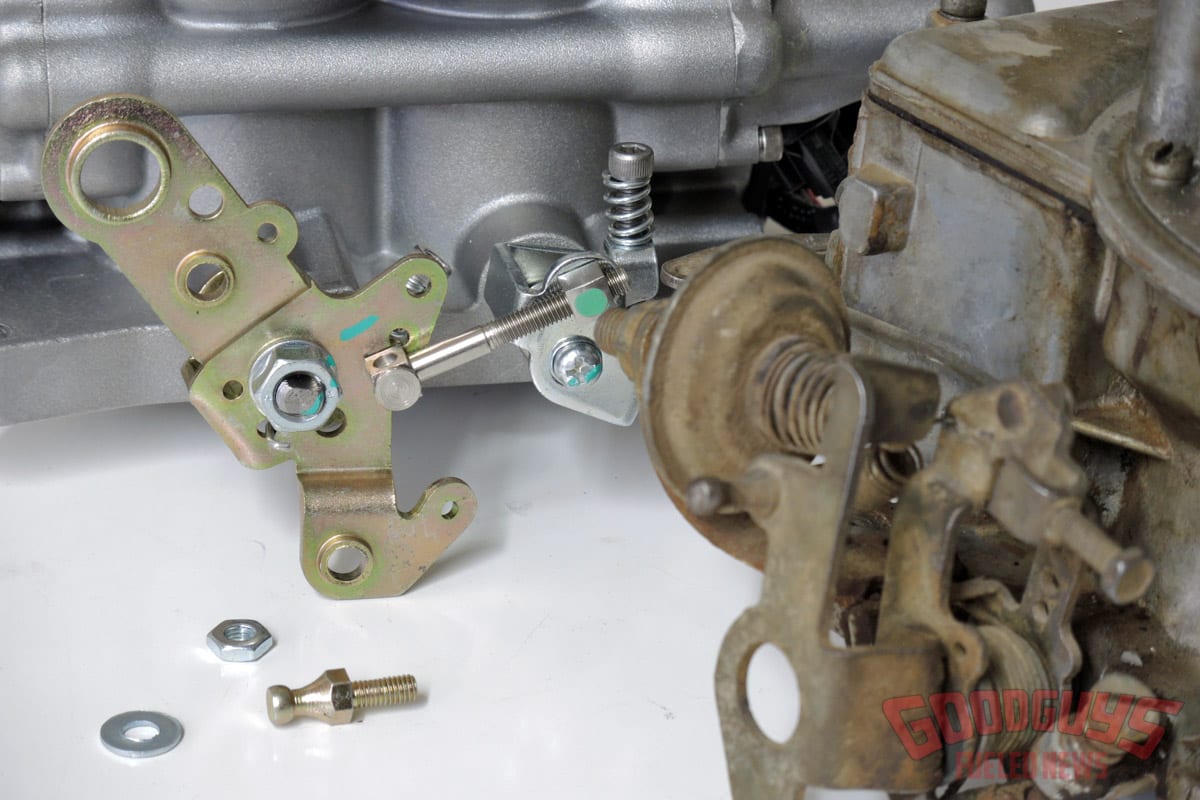

It’s a good idea to study the throttle linkage of your new throttle body to see if you’ll need any adapters for the throttle or transmission kickdown. With the universalities of these systems, it’s difficult to be prepared for every application. Be prepared! It’s no fun to get this close only to be held back due to a little linkage adapter missing.

In speaking with a number of enthusiasts who have made the swap to EFI, we wanted to share a few tips so you can be prepared to get your system installed completely and properly. The EFI manufacturers are absolutely right in stating that their systems are easy to install with hand tools and can be done in your garage, but that doesn’t necessarily mean it will be a quick Saturday morning process. Before you get started, there are a few things to consider and prepare so you don’t get held up or surprised halfway through the job.

FUEL PUMP INSTALLATION

The biggest modification you need to make for your EFI swap is to the fuel delivery system. Any EFI system requires higher fuel pressure and mechanical pumps cannot keep up. We’re talking 50psi, so an electric fuel pump is required along with high-pressure hose and fittings. This is where you really need to plan and do the job right to ensure proper operation and long life.

All the enthusiasts and builders we’ve talked to agree that the best place for the electric fuel pump is in the tank. There are several reasons for this. Pumps are made to push fuel, not pull it. The pump stays cooler thanks to the fuel engulfing it. And, the pump is a lot quieter when mounted internally.

Do it right, do it once, and plan to mount the fuel pump in the tank. This new unit from TANKS, Inc. features a recessed mount for the new fuel pump module and the sending unit. You’ll need to install the fuel pump and trim the pump module and lines to match the depth of the tank.

There are several ways to accomplish mounting the pump in the tank. First and foremost is to simply buy a new tank that is prepared for EFI. TANKS, Inc, Holley, FiTech, and others offer new tanks with a sending unit designed to secure the pump and have the fittings for a feed and return line. There are also kits available that can help you modify your stock tank to accept a pump module with a bit of time cutting and drilling.

FUEL LINES, FILTER and MORE

It should come as no surprise that with the higher fuel pressure required of EFI that you’ll need to plan to run new fuel lines. And remember, you’ll be running a feed line as well as a return line to the tank. Some EFI systems are equipped to run as a returnless system sometimes called a PWM (pulse width modulated), but again, the installers we talked to recommend to just plan on plumbing a return system.

When it comes to running a new fuel supply system, your best bet is to score a complete fuel line installation kit with your EFI system. Most manufacturers offer kits with high-pressure line, the filter, and a number of fittings/clamps to finish routing the feed and return line.

Always follow the EFI system’s recommendation when it comes to high pressure hose or a braided line. You’ll need to be updating to push-lock or AN fittings throughout, so you need to plan accordingly to avoid coming up short on a fitting or something else that will prevent you from completing the job. Be careful about using existing hard lines as they may not be able to supply the volume of fuel your system requires. And, as a rule, keep the return line the same diameter as the feed.

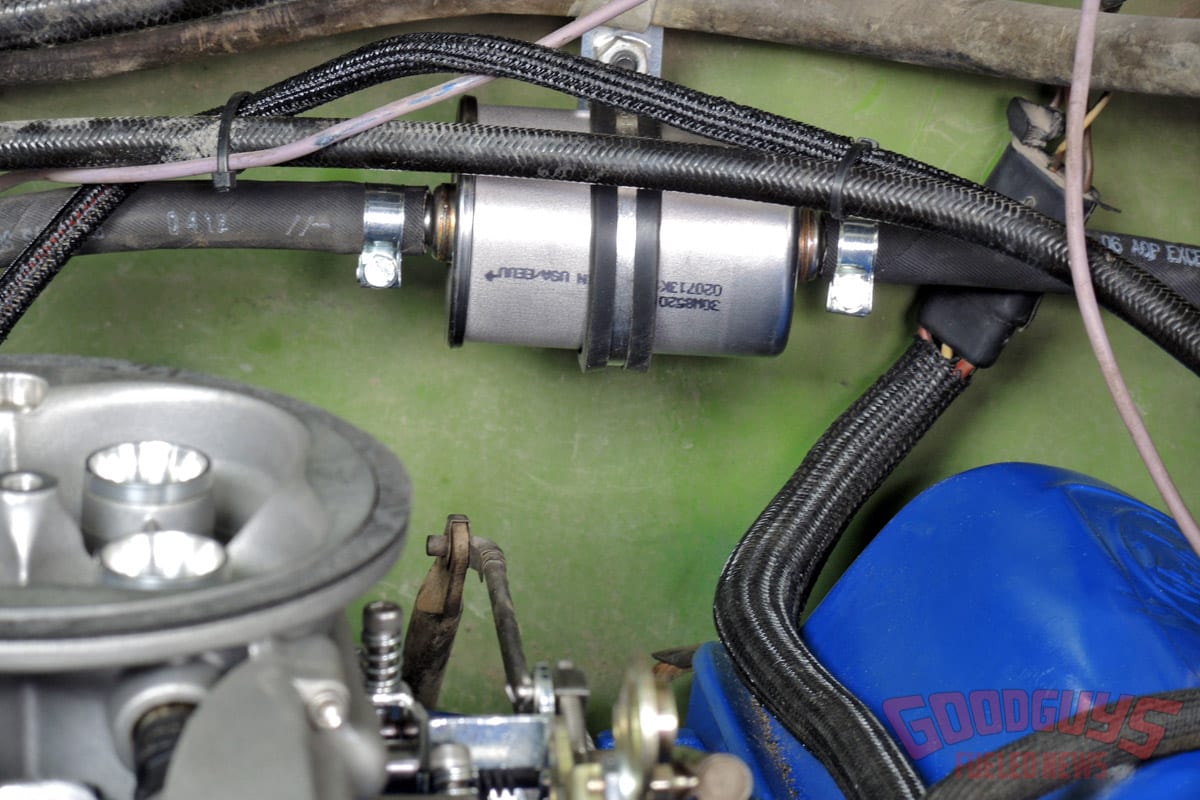

Note that some systems have a built-in regulator while others may require an external regulator. You don’t want to be surprised if your new system requires one halfway through your project, plus you’ll need to plan for a couple more fittings. Same when it comes down to the inline filter. Different models are available with fittings or nipple connections, so be sure to have the proper clamps or fittings on hand.

An inline fuel filter is required between the pump and the injectors. Filters come in a variety of sizes and with different inlet/outlets, so be prepared if you need AN fittings or high-pressure hose clamps. Also, remember that the filter is a maintenance item so be sure to keep it accessible.

Most EFI companies offer a complete hose and fitting kit. Unless you have easy access to fittings, clamps and hose, do yourself a favor and get the complete fuel line kit when purchasing the EFI system.

SENSORS

An EFI system depends on the constant feedback of several sensors, including coolant temperature, manifold pressure (MAP), throttle position (TPS), and of course, an oxygen sensor (O2) that is placed in the exhaust. Many systems have a built in MAP and TPS (some require an external MAP), but the two sensors you can always count on installing are the coolant temp and the O2 sensor.

If you’re not equipped to weld in your garage, it is recommended to drive down to a muffler shop that can handle welding the O2 sensor bung in place before you start the installation (a plug is usually supplied by the manufacturer). An alternative is a clamp-in O2 sensor assembly that wraps around the pipe and is secured with heavy duty hose clamps. For the long run, welding is the best.

The O2 sensor requires being installed in the exhaust pipe or header collector and in most cases will require a bung to be welded in place. The wide-band oxygen sensor of the EFI system provides constant feedback to the ECU so it can make adjustments to the fuel delivery. If there are any leaks around or in front of the O2 sensor, the ECU will be told there’s a lean condition and try to compensate resulting in a rich fuel mixture and poor drivability.

File this one under the ‘didn’t expect that’ category. In this example, the coolant temperature sensor for the EFI interfered with the factory throttle linkage. Not a big deal in the scheme of things, but it took some extra work to make everything clear. Also, this location was originally used for the factory temp gauge.

As for the coolant temp sensor, it shouldn’t be difficult to find a port on the heads or intake manifold, but it depends on the engine. If your engine only has one port which is used for the dash indicator, you’ll have to figure out an alternative. Also, do you have a sensor in place for an electric fan control? Just a couple things to consider when it comes installing to the coolant temperature sensor.

WIRING

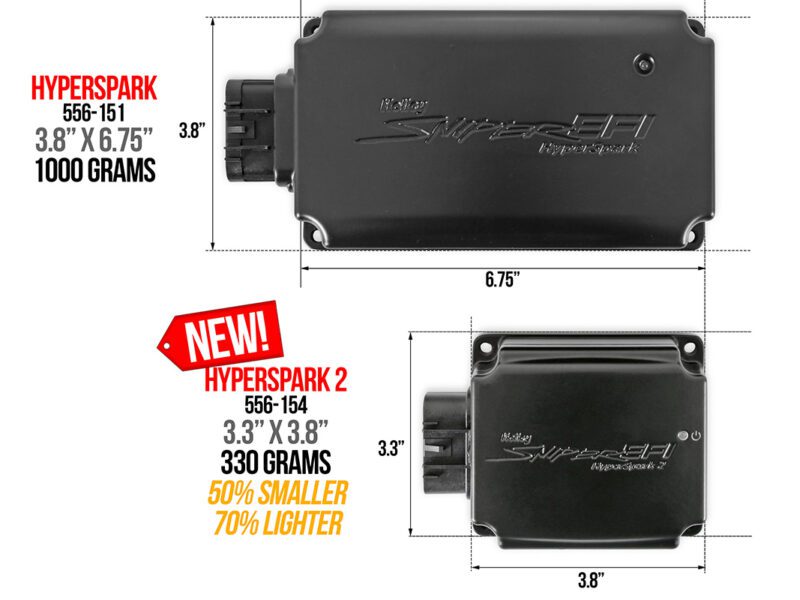

With the fuel system installed and sensors in place, your last concerns will have to do with mounting the ECU and routing the wiring harness. Most street EFI systems have done a great job with complete harnesses, labeled wiring, and matching connectors. If you’re running a port fuel system or connecting to a late-model engine there will be more connections, but take your time, read the instructions carefully, and there should be no problems.

Your new electric fuel pump will eat up some amps so if you haven’t upgraded the alternator, it’s something to think about. A factory or parts store replacement isn’t going to be suited to supply a constant 12 volts and the amps needed for the pump, ECU and other components – especially at idle and lower rpm. This old generator is not going to cut it and will need to be updated.

A couple key areas to think about when it comes to the wiring is of course the power and ground sources. It’s best to have a clean 12-volt source and ground straight to the ECU. Ideally, they should be connected straight to the battery terminals. Also, ensure there is a quality ground strap from the engine to the chassis and battery. Poor grounds will cause all sorts of bizarre issues – do it right.

We cannot stress enough the importance of the power and ground sources to the EFI system. Ideally, connect them directly to the battery terminals. Also, ensure the engine and chassis are properly grounded.

Every fuel injection system requires a trigger source. For throttle body swaps on engines with a distributor, you can usually use the coil negative terminal or better yet is a clean tach output signal from an HEI distributor or a CD ignition box. Late-model engines will have a crank or cam sensor with a matching connector.

Photos courtesy of the Manufacturers